This project aims to develop a brick-loading robot as part of the TECHBOOST project. The aim is to automate brick construction and reduce costs by using domestic bricks and robotics. The project combines the expertise of Inaro Oy and Metropolia, and aims to effectively integrate robotics into the site environment, with a particular focus on brick laying and mortar handling.

Technologies: Robotics, machine vision, automation, BIM, CAD

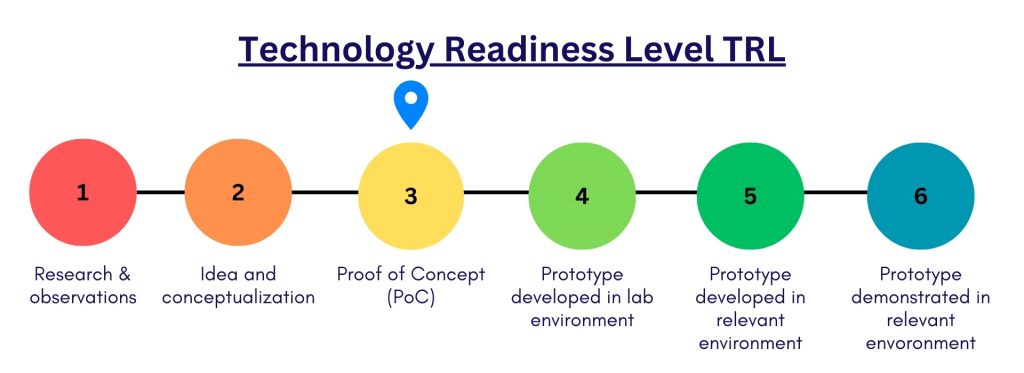

In this TECHBOOST project, we aim to develop a prototype using the newly acquired ABB GoFa-CRB 15000, based on last year’s conceptual design. In the video is an example of last autumn’s concepts. Previously, we tested the interoperability of the UR3 and the MiR mobile robot. This year, we plan to build a new prototype using the GoFa collaborative robot, Sick’s machine vision camera and OnRobot’s gripper.

Inaro Oy’s masonry robot project made significant progress in the autumn of 2024. We developed the features of the OnRobot gripper, which enhanced ABB-GoFa’s handling capabilities for bricks of different sizes and shapes, and refined brick loading and positioning using a machine vision camera.

In the masonry process, the properties of the mortar and its extrusion are key. In the first prototypes, the traditional granular mortar proved problematic, and experiments showed the need to develop a mortar feeding method and the extruder itself that would be better suited to the robotic cell. The aim for the next period is to design a mortar structure that adheres better to the brick.

Our aim is that a collaborative robot cell could demonstrate the feasibility of masonry by automating it in a laboratory setting.

Inaro Oy

Inaro Oy is a firm specialized in sustainable urban planning and architectural design, emphasizing ecological design and the use of technology.